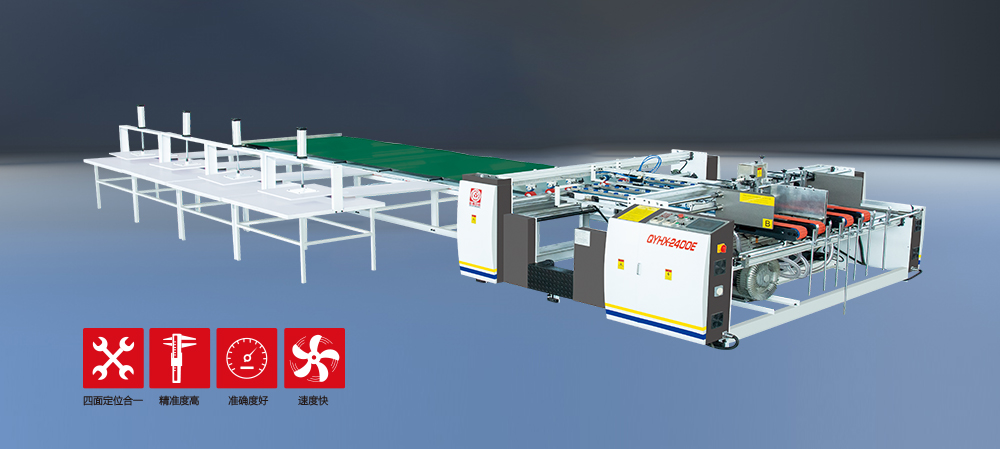

QYHX-2400E High-Speed AB Gluer Machine (Intelligent)

Main Features

Main Features

* This machine is double sheet folder gluer with multi-station tables,mainly to meet customers' long-term orders, urgent orders and high daily production requirements.

* The heating power of this machine adopts microwave heating, with low energy consumption, fast heating and high efficiency heating conduction.When working with single sheet, turn off the heating box power, which saves electricity and does not cause the oxidation degeneration of hot melt glue in the box.

* The glue unit adopts independent micro - motor drive, which can be adjusted separately.

* The machine uses dual servo feed, to ensure the stability of the equipment in the high-speed paper feed and high-speed paper feed synchronization, and the servo feed allows A and B products to set the size of the paper alone, to solve the size of the film problem.

* Adhesive using double-channel glue, respectively, hot-melt adhesives and ordinary sealing plastic to ensure that products into the container and cold storage after 100% bonding.

* Two-piece docking positioning is also used in dual-servo paper, to the machine in the low-speed bonding and high-speed bonding provides the same accuracy of consistency.

* This machine can be used as a flat box and a special-shaped box, and the front position adopts a dual purpose, which shortens the time for changing the machine.

* The machine for the dual-use machine, double sheet box and single sheet box can be produced and the double sheet box into a single box only 2 minutes to complete.

* The heating power of this machine adopts microwave heating, with low energy consumption, fast heating and high efficiency heating conduction.When working with single sheet, turn off the heating box power, which saves electricity and does not cause the oxidation degeneration of hot melt glue in the box.

* The glue unit adopts independent micro - motor drive, which can be adjusted separately.

* The machine uses dual servo feed, to ensure the stability of the equipment in the high-speed paper feed and high-speed paper feed synchronization, and the servo feed allows A and B products to set the size of the paper alone, to solve the size of the film problem.

* Adhesive using double-channel glue, respectively, hot-melt adhesives and ordinary sealing plastic to ensure that products into the container and cold storage after 100% bonding.

* Two-piece docking positioning is also used in dual-servo paper, to the machine in the low-speed bonding and high-speed bonding provides the same accuracy of consistency.

* This machine can be used as a flat box and a special-shaped box, and the front position adopts a dual purpose, which shortens the time for changing the machine.

* The machine for the dual-use machine, double sheet box and single sheet box can be produced and the double sheet box into a single box only 2 minutes to complete.

Specifications

Specifications| Model | 2400E |

| Paper size (mm) |

Max 1200×1200 Min 500×300 |

| Machine speed(p/h) | 0-3200 |

| Applicable Paper | A-F corrugated board and 5ply corrugated board |

| Dimensions (mm) | 9600*4500*1400 |

| Power(kw) | 9 |

| Total weight(kg) | 3300 |